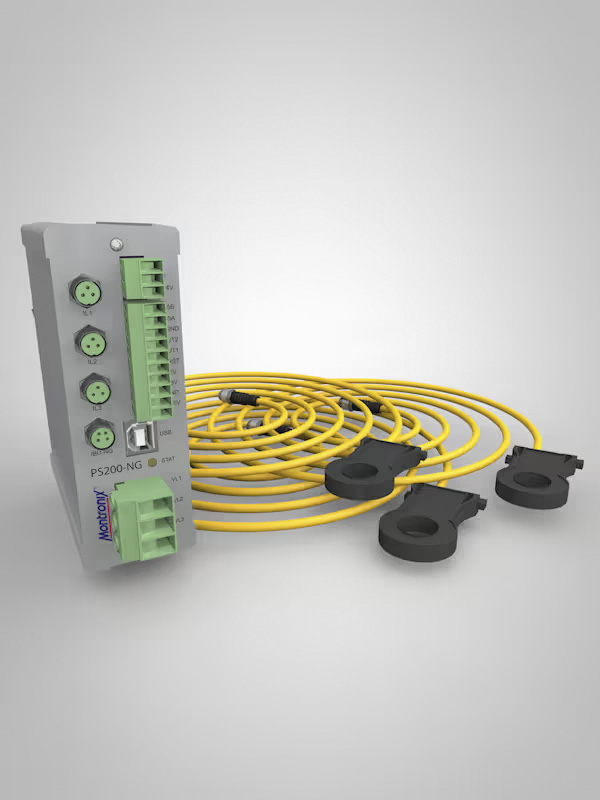

The Montronix power sensor PS-200-NG measures the input of effective electrical power of spindle and axle drives with the highest possible resolution. The power signal provided is perfectly suited for monitoring when combined with a Montronix IBU-NG.

The PS200-NG can be used with direct current motors as well as with one- or three-phase AC motors. Via current and voltage, the PS200-NG determines the input of effective power and creates a corresponding analog output signal. A multitude of amplification and filter settings are available to optimally adapt the output signal to the respective drive and process. In combination with a Montronix IBU-NG system, they can be individually set for each tool.

The PS200-NG thus offers a robust solution for monitoring tool breakage, wear and missing tools independent of the control system being used.

Deutsch

Deutsch  English

English  Italiano

Italiano