Collision Protection: Save Machines Before Damage Gets Expensive

A crash in the machine often happens in seconds, sometimes in milliseconds. And it is precisely at that moment that it is decided whether a tool breaks or the entire spindle has to be replaced. Montronix collision protection detects such events immediately and reacts faster than any control system can. This protects your machine, prevents expensive damage, and avoids downtime.

Learn more now

Collisions are Rare but Expensive: Protect Yourself!

Few companies underestimate the risks of collisions. Nevertheless, many rely on the internal machine control as the last instance. But this is exactly where the problem lies: a control system detects a collision too late. It initially interprets resistance as a normal process, such as uneven material, and increases the cutting force. By the time a limit is exceeded, it is often too late.

A typical collision effect:

- Tool moves into the wrong workpiece: If the sequence is faulty, the tool starts on the wrong part.

- Feed continues: The control does not recognize the danger and does not stop the feed.

- Spindle impacts: Impact on fixture or workpiece leads to immediate damage.

- Axes block: Bearings and drives are heavily loaded and can be damaged.

- Weeks of downtime: Repairs cause high costs and long machine downtimes.

A single incident can cost tens of thousands of euros, plus unplanned production delays and much more. Fortunately, you can protect yourself from this!

How Montronix Protects Your Machines

Montronix collision protection works independently of the machine logic. Instead of waiting for calculated values, a high-precision sensor registers every atypical vibration or acceleration in real time. In case of deviation, a signal is immediately sent to the evaluation unit, which in turn gives the emergency stop command to the control system. And all this happens in less than a millisecond.

The result:

The feed stops immediately. In most cases, it remains at a tool breakage, spindle, bearings, fixture, and the workpiece remain intact. After inserting a replacement tool, the machine can be restarted after a few minutes.

Response Time: The Decisive Factor

What does "under 1 millisecond" mean?

Most machine controls take between 10 and 100 milliseconds to react to a problem. During this time, the tool continues to move at high speed, increasing the collision damage. Montronix reacts in less than a millisecond. This means: collision protection intervenes before damage accumulates.

What happens after detection?

The Montronix evaluation unit is firmly connected to the emergency stop input of the control system. When an adjustable threshold is exceeded, the safety stop is triggered immediately by giving the feed emergency stop signal via hard wiring between the fast output of the Montronix unit and the fast input of the machine control. In parallel, the system can give a visual or acoustic warning, record data, or send alarm messages by email. This way, the collision is documented and traceable.

Which Components are Used?

Montronix collision protection is based on a modular system of sensors and evaluation unit. Depending on the application, the components can be flexibly combined. At the center are three building blocks:

Pulse Plus or Pulse M12 Plus

Both sensors are based on modern MEMS technology and measure accelerations in three axes. They detect the finest shocks, impacts, and vibrations in real time. The Pulse series was specially developed for use in machine tools.

Features at a glance:

- Measurement in X, Y, and Z axes simultaneously: Detects all movements in three dimensions for complete process analysis.

- High resolution: Detects even the smallest movement deviations in real time.

- Compact aluminum housing: Encapsulated for maximum robustness and durability.

- Protection class IP67: Resistant to oil, dust, and moisture.

- Underwater use: Sensor works reliably up to 6 m depth.

- Easy installation: Mounting by screw or optionally with magnetic foot.

- Wide range of applications: On spindles, axis modules, control cabinets, pumps, or workpiece carriers.

The choice between Pulse Plus and Pulse M12 Plus depends on the available installation space. Both deliver identical measurement results.

IBU Plus or IBU Plus NX

These evaluation units take on the central task in collision protection. They analyze the sensor signals in real time and trigger the shutdown signal if necessary. The IBU Plus is designed for one sensor and the IBU Plus NX for up to 4 sensors.

Advantages in use:

- Comparison of measurement data: Comparison with freely definable limit values.

- Lightning-fast reaction: Immediate notification or stop in case of deviations.

- Independent of the machine control: Flexible use in any system.

- Easy integration: Connection via digital inputs and outputs possible.

- Full functionality: Can also be used without Profibus or Profinet connection.

The IBU Plus variants are suitable for both new machines and retrofits. Thanks to the compact design, the system can be easily installed in the control cabinet.

Dull Collision

A dull collision occurs when an object is hit at very low speed. No vibration is generated here, only pressure on the machine structure, which is why a dull collision is best monitored with a Strainlink system. The pressure on a surface is monitored very sensitively via strain gauges. The sensitivity can be set so finely that even the pressure of a finger on a steel beam can be detected. This type of monitoring is much less common in practice and is usually used as a supplement. With an IBU Plus NX, for example, two Pulse Plus vibration sensors and two SLA NG amplifiers for up to four Strainlink sensors can be connected and monitored simultaneously.

Spectra ONE

For complex applications or when, in addition to collision monitoring, tool diagnostics and process monitoring are also required, Spectra ONE can be integrated. This system significantly expands the functionality.

What Spectra ONE does:

- Complete logging: All sensor events are fully recorded.

- Real-time visualization: Measurement data is displayed and monitored immediately.

- Documentation of processes: Every machining step is traceably recorded.

- Combination of several sensor types: Flexible use for comprehensive analyses.

- Series monitoring and quality analysis: Ideal for continuous control in series production.

Spectra ONE can be seamlessly combined with IBU Plus, Pulse Plus sensors, and other components from the Montronix portfolio. It is particularly suitable for systems with high quality requirements or for preparation for predictive maintenance.

Collision Protection in Unmanned Operation

When machines run without operators, direct control is missing. Robots load, workpieces are automatically clamped, the machining program starts. But what happens if a mistake occurs?

A misaligned workpiece, a wrongly gripped part, or a twisted clamping device is enough to trigger a collision. Without monitoring, the process continues until it crashes.

Montronix collision protection detects such deviations via sensors that react directly to atypical movements and vibrations. Even before the collision spreads, the machine stops. This protects spindle, fixture, and workpiece. The event is documented, and production continues after a short break. Especially in unmanned operation, collision protection secures the last critical seconds when no one can intervene.

Contact us nowWhy Montronix?

Real-time Reaction Without Calculation Logic

Our sensors measure real acceleration, not calculated values or estimates. This means: it does not wait to see if the motor current increases or the axis value shifts. The reaction occurs immediately when the machine moves unusually.

Independent of the Machine Control

Whether Siemens, Fanuc, Heidenhain, or other controls, our system works completely independently. It only uses digital inputs for emergency stop or soft stop and can communicate with existing systems via Profinet, Profibus, or I/O.

Quick Installation, Easy Integration

The sensors are mounted directly at the critical point. Either screwed or with a magnetic foot. Then the cable is routed to the control cabinet to the IBU Plus or IBU Plus NX. No software intervention required. No intervention in the machine logic.

Scalable and Expandable

If you want more later, such as tool monitoring, wear detection, or real-time documentation, you can expand at any time with Spectra ONE or additional sensors like the PS200. The Pulse Plus sensor remains the same.

Proven Technology with Test Setup

Montronix offers you the opportunity to test the system in your own machine. Without obligation, with full support from our experts. This way you can see the function for yourself.

For Which Machines is the System Suitable?

The Montronix collision protection can be flexibly integrated into almost any machine tool. The sensors are based on physical measurement, not on machine protocols. This makes them independent of control, machine type, or year of manufacture.

Machining centers

Especially in machining centers with automatic tool change and tight cycles, risks quickly arise. The sensor stops when it contacts the table, fixture, or workpiece.

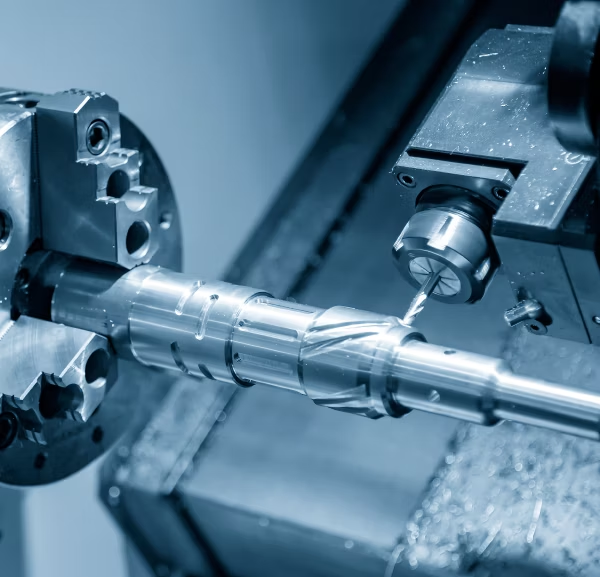

Lathes

High speeds and large workpieces generate strong forces. In case of clamping errors or program errors, the collision can be dramatic, protection reacts immediately.

Grinding machines

Sensitive grinding wheels and minimal distance between workpiece and wheel require maximum precision. A misposition quickly leads to damage.

Automated cells

Robots and gantries work reliably, but without visual inspection. The sensor detects when something does not go as planned, for example with incorrect workpiece positioning.

Special machines and units

Even complex setups or older systems benefit from protection. Installation is simple, the effect is immediately noticeable.

In short: wherever something moves, something can go wrong. And that's exactly where Montronix protects.

Contact

Do you want to protect your machine before it gets expensive? Or do you have a specific project with or without automation that needs to be secured? Then talk to us. We will advise you individually, put together the right system for you, and support you up to commissioning.

Send inquiry now

DE

DE  EN

EN  IT

IT