Measure tool wear and prevent damage in time

Tools wear down gradually. The problem often goes unnoticed until it leads to dimensional deviations, scrap, or machine downtime. At Montronix, we measure tool wear directly in the machining process. Our sensors detect even the smallest deviations immediately and report them early, before your production suffers damage.

Learn more now

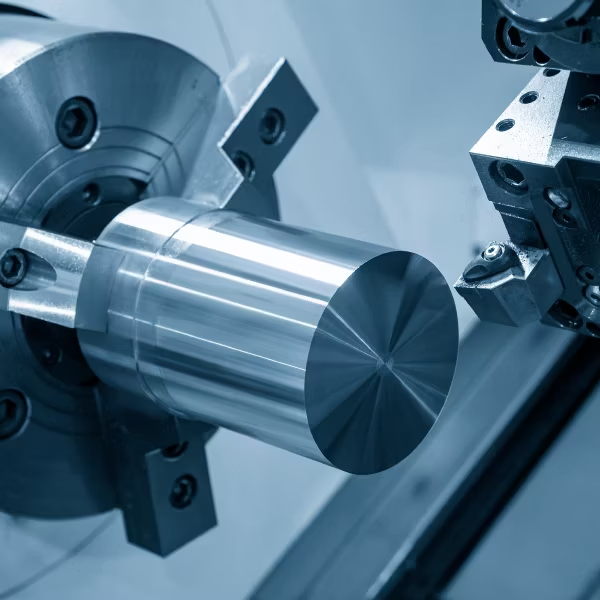

Measuring tool wear: the invisible danger in the machining process

Wear develops quietly and continuously. Early signs such as changes in forces, increased vibration, and declining cutting quality often go unnoticed. Without continuous monitoring, the condition of the tool remains unknown. The result is defective parts or sudden tool breakage.

How tool wear measurement works

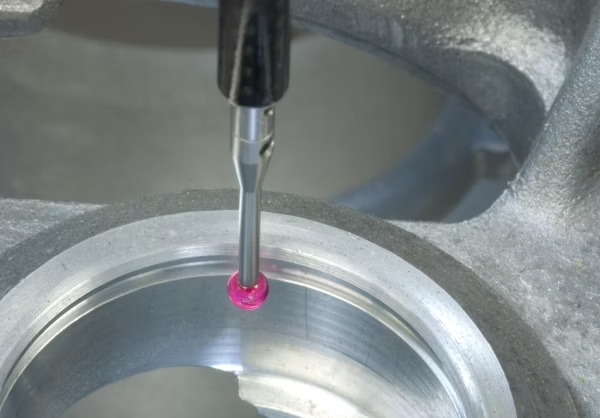

Our systems monitor ongoing machining processes and detect deviations in tool behavior. The sensors analyze changes in power, vibration, and cutting force. The system compares these values with reference cycles. As soon as values move outside defined tolerances, an automatic warning or machine stop is triggered.

Contact us nowOur solution at a glance

No machine tool is like another, and no manufacturing process is exactly the same. That’s why Montronix offers a wide range of sensors, evaluation units, interface modules, and software components.

Which combination is right depends on your requirements: machine type, workpiece, cycle times, quality requirements, and more. Here are typical components from Montronix for detecting tool wear:

Additional system components

To use these sensors efficiently for wear detection, the following components are combined:

- Spectra ONE: Evaluation unit for signal processing, threshold control, and machine interaction

- SensorHub NX / SensorHub AD / Hub DIO: Signal distribution, system integration, IO handling

- IBU Plus: Compact solution for machine stop and alarm handling when limits are exceeded

Challenges in measuring tool wear

- Complex preparation and long measuring times:

Measuring tool wear is often associated with high organizational effort. The workpiece must be precisely positioned, clamped, and possibly even manually aligned. Especially with tactile systems, this is crucial for reproducible results. This process not only takes time but also requires concentration and care, significantly slowing down operations in everyday work. - Dependence on operating personnel and lack of comparability:

Traditional measuring systems usually require trained specialist personnel for both operation and evaluation. This not only increases susceptibility to errors but also makes comparability over time or between different components more difficult. When measurement results depend heavily on individual handling, process reliability suffers — especially in series production or when assessing tool life.

Technical advantages of our sensor solutions

Our sensors provide reliable measurement data in real time and can be flexibly integrated into a wide variety of machines. Installation requires minimal intervention in the control system.

Real-time measurement

The sensors record power, vibration, or cutting force with microsecond resolution directly in the ongoing machining process.

Independence from the control system

The sensor solutions work with any CNC machine, as they operate via separate inputs and outputs, as well as via Profibus and Profinet, and do not require a control interface.

Easy retrofitting

Installation is usually completed within a single working day.

Modular design

Sensors and evaluation units can be flexibly combined and expanded.

Our Services at a Glance

We support you not only with technology, but with a complete service package: from the initial analysis to training your employees.

- System consulting: We analyze your requirements and recommend the right components, taking into account machine type, process, control system, and budget.

- Installation and commissioning: Our technicians assist you during installation. The systems can be retrofitted quickly, even with minimal intervention in the control system. Commissioning usually takes place within one working day.

- Trial setup and pilot project: You test the system directly on your machine with your workpieces. This way you can see the effectiveness of the sensors before purchase.

- Training and support: We train your employees in using the system. If you have questions, you can reach our technicians directly without detours.

How You Benefit from Tool Wear Measurement

Continuous measurement of tool wear provides control during the ongoing process and delivers clear benefits for quality, availability, and costs.

Reduction of scrap

The system detects early when cutting force, vibration, or power change. This allows you to stop the process in time before the first defective part. Especially in series production, you reduce scrap and avoid unnecessary rework.

Extension of tool life

You no longer replace tools out of suspicion, but specifically when wear begins. This way you fully utilize the service life of each tool. This can save up to 30% of tool costs per machine.

Prevention of machine downtime

The system automatically reports early damage to tools or spindles. You can intervene before a shutdown occurs. This increases the availability of your machine even in unmanned operation.

Documentation and traceability

All measurement data is automatically recorded and archived. You can immediately identify wear patterns, outliers, or tolerance violations. The data provides clarity for quality assurance, traceability, and process optimization, giving you 100% control in every machine.

Contact

Do you want to measure tool wear and protect your machines? Then write to us or call us. We will advise you without obligation and recommend the right solution for your application.

Send request nowFAQ: Frequently Asked Questions about Measuring Tool Wear

How does the system detect initial tool wear?

The system continuously analyzes values such as power, cutting force, and vibration. It compares these with a learned reference value. As soon as the deviation exceeds a defined limit, a notification is issued. The sensors respond even to the smallest changes that operating personnel cannot detect.

Does it work on older machines?

Yes, the sensors work independently of the control system. You connect the components directly to existing inputs and outputs or to Profibus or Profinet. The system can also be easily integrated into machines without modern CNC. Many customers retrofit their systems within a day.

Is commissioning complicated?

No, the systems are preconfigured and easy to install. The sensors usually require no calibration and recognize the reference process after teaching. A technician will show you how to operate it on site. After that, you can use the monitoring independently in daily operations.

Can I test the system before buying it?

Yes, Montronix offers a non-binding trial installation. You receive the system for a limited period to use on your machine. Our team supports the setup and helps interpret the measurement results. This way you make an informed investment decision based on your own data.

DE

DE  EN

EN  IT

IT