Tool Monitoring: Our Complete System

Montronix offers tool monitoring systems for all types of cutting machine tools. With our intelligent sensor solutions, you can detect tool breakage, wear, collisions, and process errors in real time.

Learn more now

Challenges in Tool and Process Monitoring

In modern manufacturing environments, companies face a variety of technical and organizational challenges. Especially in machining, tool changes, or automated processes, reliable monitoring is essential, but it is often associated with hurdles:

Tool or process monitoring – what's the difference?

With process monitoring, the entire cycle of a machining process on a machine is monitored, or at least the section the user wants to monitor. The term tool monitoring would actually mean monitoring only one or several tools as long as the selected tool(s) are engaged, but in recent years, the terms tool and process monitoring have been used almost interchangeably.

Lack of transparency in the machining process

Instead of relying on manual checks or experience, tool monitoring runs continuously in the background. This minimizes unplanned downtime and keeps your production running.

Making processes measurable instead of just guessing

It is often unclear when and why a tool wears out or fails. Without continuous data, the basis for preventive measures is missing. Errors are usually only detected after scrap/NOK parts (not OK parts) or machine damage.

Unexpected machine downtime

Collisions, tool breakage, or vibrations are only noticed in many companies when it is too late. The consequences: unplanned downtime, high repair costs, and failure of entire production lines.

Production of NOK parts

Drill breaks during the unmanned shift, a piece of the drill remains in a part, and then dozens of parts are produced without a hole. The error goes unnoticed and the parts are delivered to the customer or sent for further processing. Anyone with a few years of experience knows the consequences: unplanned rework, which causes time and costs, and plenty of sarcastic remarks. With a Montronix tool monitoring system, this would not have happened.

Manual checks are error-prone

Especially with small batch sizes or complex machining processes, manual tool checks are unreliable, time-consuming, and highly dependent on the experience of the personnel.

Different machine types & controls

Many monitoring solutions are not universally applicable. Different machine controls, years of manufacture, or systems make it difficult to integrate classic sensor technology. Not so with Montronix, because the Montronix system is control-independent and can work with any CNC control that has free inputs and outputs.

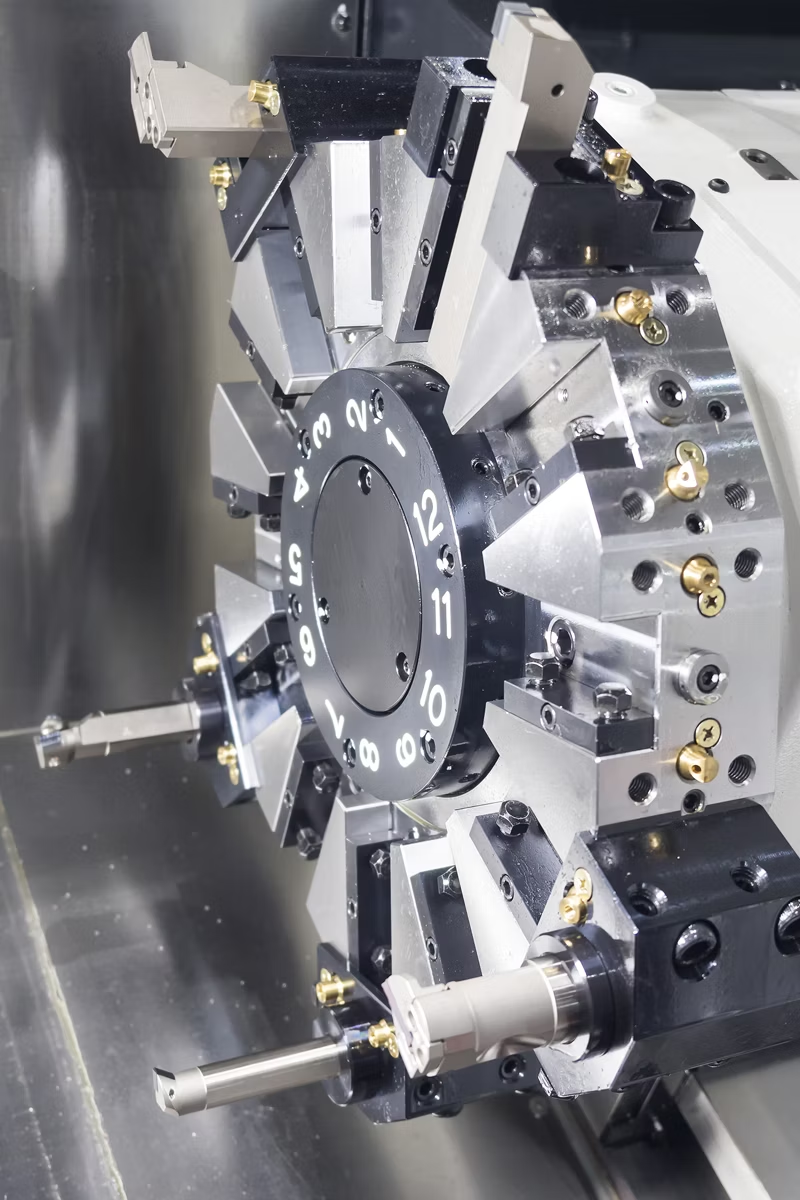

Areas of Application for Our Solutions

Montronix monitoring solutions are used wherever the highest precision, process reliability, and machine availability are required. Our sensors and systems can be flexibly integrated into a wide variety of manufacturing environments, regardless of machine type, control, or year of manufacture.

Typical areas of application for tool or process monitoring are:

- Machining technology: Machining centers, lathes, milling machines, mill-turn machines, boring mills, grinding machines, shaping machines, transfer lines, multi-spindle systems, and special machines for tool monitoring, process control, wear detection, and collision detection.

- Robot and workpiece handling systems: Monitoring of load, alignment, collision, and movement patterns in automated production processes.

Untypical areas of application for our tool or process monitoring are numerous, because it is always about monitoring the change of a physical quantity over time to ensure that no impermissible change occurs compared to the desired processes, i.e., that neither the physical quantity at time X is greater or less than the target value + freely selectable tolerance, nor that the physical quantity matches the target but not at time X, but earlier or later.

You can trust Montronix products for these applications

Tool monitoring plays a central role in modern manufacturing processes, especially in machining, drilling, milling, turning, or grinding. Its goal is to continuously control tools and processes to detect and prevent errors, downtime, and quality losses at an early stage.

The most important tasks of our products include:

- Detection of tool breakage: Monitoring identifies abrupt changes in force, vibration, or power, typical of broken or torn-out tools.

- Detection of tool wear: Continuous analysis of process data makes gradual wear visible before dimensional deviations or surface defects occur.

- Reporting missing or incorrect tools: Through reference comparisons, the system immediately detects if a tool is not correctly clamped or not present at all.

- Monitoring machining behavior: Deviations in feed, cutting force, or resonance frequencies indicate process instability or material deviations.

- Avoiding collisions: In combination with other sensor data, dangerous conditions such as stock errors or collisions between tool and workpiece can be detected and the process stopped.

- Process documentation and quality assurance: The recorded data also serves traceability and analysis, e.g., in series production, auditing, or complaint management.

With Montronix systems, this monitoring is fully automatic, in near real-time, and independent of the machine control.

The Montronix System for Perfect Tool Monitoring

For reliable and automated tool monitoring, you need more than just a sensor. Montronix offers an individual system that flexibly adapts to your machine and process. From the sensor to data evaluation, all components work together perfectly.

This is how a typical monitoring system works:

- Sensors: Detection of forces, vibrations, power, or structure-borne noise, directly at the tool, spindle, or in the machine structure.

- Signal amplification & processing: The sensor signals are amplified, filtered, and prepared for analysis.

- Evaluation unit (e.g., Spectra ONE): Comparison with reference values, detection of deviations, and triggering of warnings or machine stop.

- Integration & visualization: Connection to control, display on HMI or PC, storage, and evaluation of process data.

Our Key Components at a Glance

Application Examples

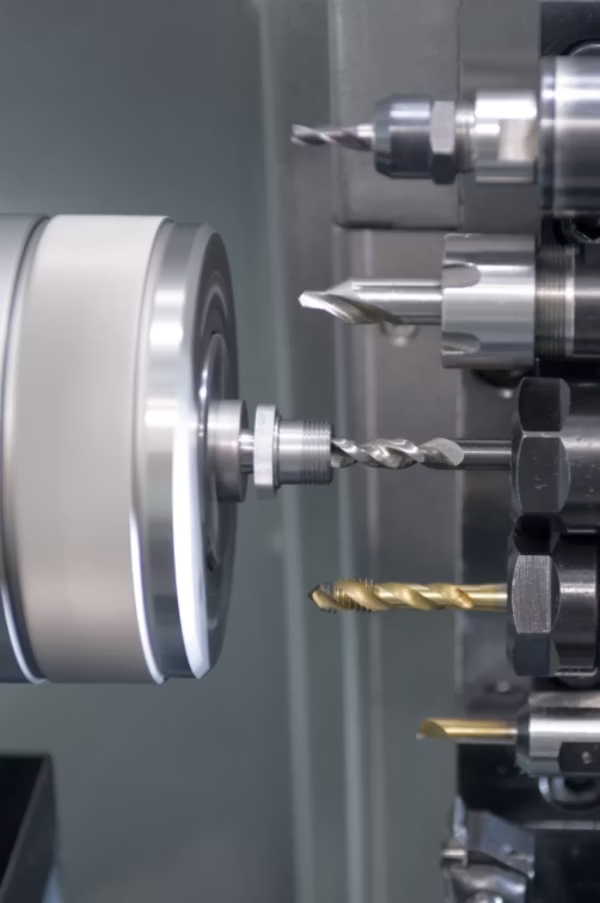

Tool Monitoring in a CNC Machining Center

A manufacturer of precision components wants to avoid tool breakage and undetected wear in an automated milling center. Particularly critical: the use of small drills < 2 mm at high feed rates.

Components used:

- Pulse Plus / Pulse M12 Plus:

- MEMS acceleration sensor for detecting the smallest changes in vibration

- Can be mounted directly on the spindle or axis unit

- Spectra ONE:

- Real-time evaluation of sensor signals

- Comparison with reference data to identify tool breakage or wear

- Machine stop or warning message in case of deviation

Alternative option:

- Integration via SensorHub or IBU Plus:

- Flexible integration without intervention in the machine control

Result:

- Tool breakage is detected early

- Scrap is reduced

- The tool life can be fully utilized without risk

Process Monitoring in a Multi-Spindle Lathe

A supplier for automotive components uses a multi-spindle lathe for series production. However, different material batches and tools regularly lead to unnoticed quality deviations and rework.

Components used:

- PS200-NG:

- Power sensor for high-resolution measurement of active power on spindle and feed drives

- Detects process deviations through power changes

- PS200-NG amplifier module (set with 3 Hall sensors):

- Filter and amplification settings for different tools and materials

- Adaptable to current, voltage, and load profiles

- SensorHub NX / IBU Plus:

- Transmission of signals to the evaluation system

- Documentation and live monitoring of the process

- Spectra ONE:

- Real-time evaluation of sensor signals

- Comparison with reference data to identify tool breakage or wear

- Machine stop or warning message in case of deviation

Result:

- Scrap parts are detected before further processing

- Batch differences can be evaluated

- Process deviations are automatically documented

Areas of Application for Our Solutions

Montronix monitoring solutions are used wherever the highest precision, process reliability, and machine availability are required. Our sensors and systems can be flexibly integrated into a wide variety of manufacturing environments, regardless of machine type, control, or year of manufacture.

Monitoring cutting micro-breakouts in a duo lathe

An automotive manufacturer uses a lathe with 2 spindles for series production. They want to detect the smallest breakouts on the turning tool to ensure the quality of the components.

Components used:

- 2x Retrobolt ICA:

- Force sensor for high-resolution measurement of forces and force breakouts on the tool

- Detects process deviations through force changes

- Spectra ONE:

- Real-time evaluation of sensor signals

- Comparison with reference data to identify tool breakage or wear

- Machine stop or warning message in case of deviation

Result:

- The smallest breakouts on the turning tools are detected

- No surface problems

- Process deviations are automatically documented

Advantages of Tool Monitoring by Montronix

Avoid damage through immediate error detection

Montronix systems detect tool breakage, collisions, or air cuts in real time and send the signal to the control to stop machining or start another action desired by the operator.

Reduce downtime through automated monitoring

Instead of relying on manual checks or experience, tool monitoring runs continuously in the background. This minimizes unplanned downtime and keeps your production running.

Make processes measurable instead of just guessing

Whether cutting force, vibration, or spindle power: With Montronix, your processes become transparent for the first time. This enables targeted optimizations and well-founded decisions based on real data.

Use tools more efficiently to increase tool life

Precise monitoring allows each tool to be used up to the wear limit without risk. This saves tool costs and reduces unnecessary changes.

Ensure quality, even with small diameters or micro tools

Our sensors detect even the smallest changes, e.g., with micro-breakouts on cutting inserts or drills under 2 mm. This ensures the highest machining quality.

Quick retrofit: control-independent and flexible

Whether new or existing machines: Montronix systems can be easily retrofitted into the control with just a few interventions, ideal even for heterogeneous machine parks.

Ideal for shift operation & shortage of skilled workers thanks to easy operation

The monitoring runs fully automatically and is learning-based. This keeps the process stable even when experience or personnel are in short supply.

Ready for precise tool monitoring?

Whether tool monitoring, process control, or machine protection: Together we will find the optimal solution for your application. Our experts will advise you individually, quickly, and without obligation.

Contact us nowFrequently Asked Questions about Tool Monitoring

Which components are part of tool monitoring?

A typical Montronix system consists of:

- Sensors (e.g., Pulse Plus, Hall sensors, RetroBolt)

- Amplifiers for signal processing (e.g., PS200-NG)

- Evaluation unit (e.g., Spectra ONE)

- Hubs / interface modules (e.g., SensorHub NX or Hub DIO)

- Visualization via HMI

All components work together and enable fully automatic monitoring.

Is Montronix tool monitoring also suitable for older machines?

Yes, all Montronix systems are designed to be control-independent and can be easily integrated into existing machines, even in mixed or older machine parks. Retrofitting is often possible within a few hours.

What types of tool errors can be detected?

Our systems detect, among other things, tool breakage, severe wear, missing or incorrectly inserted tools, as well as irregularities in the cutting process. Material defects, collisions, or vibrations can also be reliably detected. But in principle, anything that causes a change in a physical quantity over time can be monitored.

Which sensor do I need?

Choosing the right sensor is not easy and always depends on what you want to monitor on which machine. But we have the experience of tens of thousands of installations, so just contact us and we will be happy to advise you.

DE

DE  EN

EN  IT

IT