Machine Monitoring: Intelligent, Simple, and Always Protected

Montronix provides a complete system for machine monitoring that detects problems before they cause expensive damage. Our sensors analyze processes in real time, stop at deviations, and thus ensure quality and availability. You avoid downtimes, reduce costs, and extend the service life of your tools and machines.

Learn more now

Challenges in Machine Monitoring

In manufacturing, fractions of a second are often enough to cause damage: a drill breaks, a collision destroys the spindle, or vibrations affect dimensional accuracy.

Without continuous monitoring, operators only recognize the cause when scrap parts are produced or repairs are needed. Different controls and machine types make it difficult to integrate a solution. If experienced personnel are lacking, operators react too late.

Core Components of Montronix Machine Monitoring

Effective machine monitoring is based on coordinated modules. Each component has a task: from detection to evaluation and display.

Advantages of Machine Monitoring by Montronix

Avoid Damage in a Planned Way

The system detects collisions or overloads and informs the control in less than 1 millisecond. You save repair costs and prevent downtimes.

Optimal Use of Tool Life

Each tool is used up to its actual wear limit. This reduces costs by up to 30% and lowers unproductive changeover times.

Ensure Quality Permanently

The system detects changes in cutting behavior before tolerances are violated. Your components remain consistently high quality.

Minimize Unplanned Downtimes

Early warnings enable quick intervention. Even in unmanned operation, monitoring reacts reliably.

Make Processes Transparent

With up to 26,667 data points per axis, you get a clear database for optimizations.

Flexible Integration

The systems are control-independent and also suitable for retrofit projects.

Areas of Application for Our Solutions

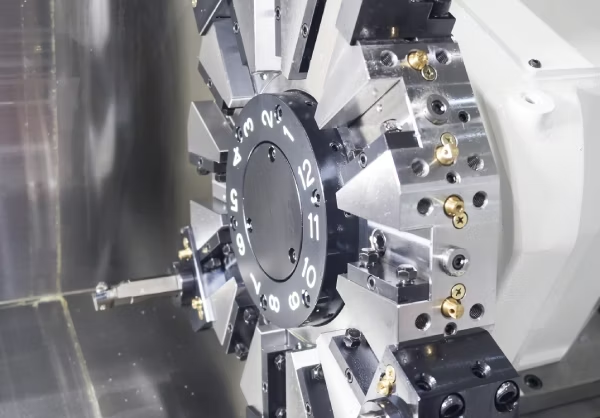

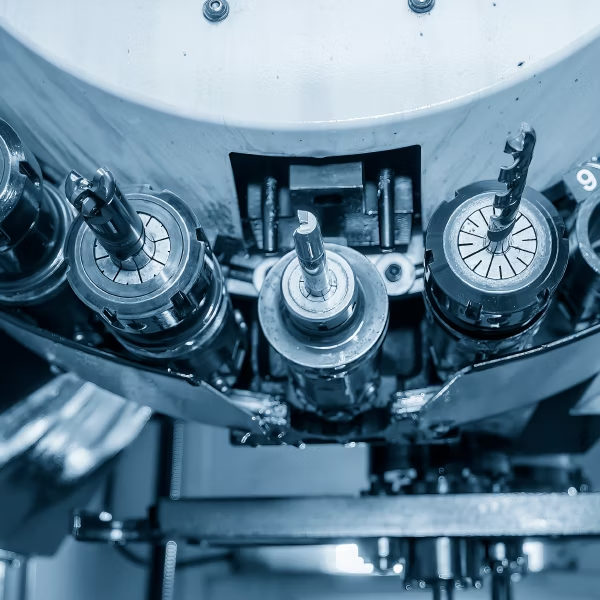

- Machining: Machining, milling, and turning centers, grinding machines, boring mills

- Automated transfer lines: with multi-spindle drilling heads

- Robot and handling systems: Detection of load peaks and collisions

- Pumps and units: Continuous monitoring of drives

- Special machines: Individually adapted sensor solutions

You Can Rely on Montronix Products for These Issues

Machine monitoring is indispensable in modern manufacturing processes, e.g. in machining. The goal is to avoid errors, downtimes, and quality losses at an early stage.

Our systems take care of:

- Tool breakage: Changes in force or vibration stop the process immediately.

- Tool wear: Gradual wear becomes visible before deviations occur.

- Missing tools: Incorrect equipment is detected immediately.

- Machining behavior: Deviations in feed or cutting force indicate instabilities.

- Collisions: Dimensional errors are detected and damage is prevented.

- Process documentation: Complete recording for quality assurance and audits.

The Montronix System for Perfect Machine Monitoring

For automated monitoring, a coordinated system is required. Montronix combines all components into one solution.

How it works:

- Sensors: Detection of forces, vibrations, or structure-borne sound.

- Signal amplification: Adjustment of measured values.

- Evaluation unit: Comparison with references and stop in case of deviations.

- Interfaces: Connection to controls via Profibus, Profinet, or digital I/O.

- Visualization: Documentation and analysis of data.

Start Now with Machine Monitoring from Montronix

Avoid expensive failures and secure your production quality. Request an individual offer today and experience how our systems make your production stable and transparent.

Send inquiry nowFAQ: Frequently Asked Questions about Machine Monitoring

How fast does the monitoring react?

Our sensors constantly monitor the sensor signals and compare them in size and timing with the reference signals. Any deviation outside the tolerances specified by the machine operator immediately leads to a message to the machine control with the aim of stopping the process before damage occurs. This reaction speed is crucial to protect components, tools, and machine parts. As a result, you significantly reduce downtime and consequential costs.

Is the system also suitable for older machines?

Yes, the systems are completely control-independent. They can be integrated into almost any machine via digital inputs and outputs or fieldbus. This allows you to modernize existing systems without major intervention in the control. This way, even older machine parks benefit from modern machine monitoring technology.

Which sensors are suitable for my application?

The selection depends on what you want to monitor. For drives, we recommend power sensors, for collisions vibration sensors, and for cutting forces force sensors. We analyze your machine and process together to select the optimal combination.

Can I test the system before investing?

Yes, Montronix offers test installations under real production conditions. This way you see the performance in your own machine with your processes. This option reduces investment risks and provides decision-making certainty. After the test phase, you can continue to use the system directly.

DE

DE  EN

EN  IT

IT