3-Axis Acceleration Sensor: Detecting Movements from All Directions

Our 3-axis acceleration sensors detect vibrations, collisions, and movements in real time. The Pulse Plus and Pulse M12 Plus models are suitable for a wide range of industrial applications, from machine tools to pump systems. By measuring in three axes simultaneously, they provide a complete picture of every movement. This allows critical situations to be detected early, machines to be protected, and processes to be specifically improved.

Learn more now

What is a 3-Axis Acceleration Sensor?

A 3-axis acceleration sensor detects forces that occur during movements and vibrations and converts them into electrical signals. It measures how much an object accelerates, i.e., how quickly its speed changes in a certain direction.

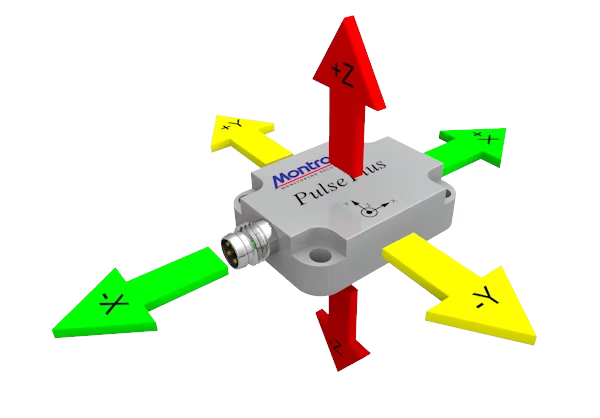

A sensor with 3-axis technology provides significantly more information than a 1-axis sensor: it detects not only linear movements but also complex vibration patterns in all three spatial directions (X, Y, Z).

Technically, the measurement is based on a mass-spring system in a MEMS chip (microelectromechanical system). When the sensor is moved, a force acts on the internal mass. This force generates an electrical signal that is proportional to the acceleration.

3-Axis Acceleration Sensors from Montronix

The Pulse Plus and Pulse M12 Plus acceleration sensors from Montronix offer reliable, high-precision detection of vibrations, shocks, and collisions in real time with minimal effort for installation and operation. Both models are based on modern MEMS technology with 3-axis measurement.

Technical Data Comparison

When is Which Sensor the Right One?

Pulse Plus

Ideal when there is enough space and a wide frequency range is important – for example, for extensive analyses or mobile measuring systems such as the WiFi Box Plus.

Pulse M12 Plus

Perfect for tight installation situations without sacrificing accuracy. Especially suitable for spindles, compact modules, and space-critical areas.

Why three axes?

Movements and vibrations in machines are rarely one-dimensional. A tool can vibrate in several directions at once, a collision often acts obliquely on the component, and imbalances create complex patterns.

A 3-axis acceleration sensor responds to all these movements and gives you a complete picture. That is exactly what makes the difference in practice: More safety, faster diagnosis, less downtime.

Contact us now

How It Works: How a 3-Axis Acceleration Sensor Measures Movements

At its core, the sensor works according to the mass-spring principle:

Inside is a small mass that presses against a spring when moved. This force is transferred to a piezoelectric material or a MEMS chip. This generates an electrical voltage, which is converted into a precise signal.

The special feature of Montronix sensors: They measure in three axes simultaneously. This means they also detect complex vibrations or multiple superimposed oscillations – something many other sensors can only calculate or partially ignore.

What Can Our 3-Axis Acceleration Sensor Actually Do?

Collision Protection

Detects within 1 millisecond whether tools or axes hit an obstacle. This usually keeps the spindle intact – expensive downtimes are prevented.

Vibration Monitoring

Detects imbalances, bearing damage, or unstable processes. Early intervention saves time and money.

Tool Monitoring

Reports tool breakage or heavily worn tools by changed vibration behavior.

Process Optimization

Real-time data provides information about machining quality. Ideal for fine-tuning your production.

Machine Diagnostics

Sensors provide precise signals for mechanical problems, e.g., loose components or defective guides.

Condition-Based Maintenance

Wear and damage are detected early, maintenance can be planned accordingly.

Advantages of 3-Axis Sensors at a Glance

An acceleration sensor with 3-axis measurement offers more than just data. It is an active tool that protects your production, makes your machines more efficient, and helps you detect problems before they even arise.

- Actively protect machines: Collisions or shocks are detected immediately – machine damage is prevented before it occurs.

- Avoid tool breakage: Changed vibration behavior indicates wear or breakage early. The sensor reports in real time.

- Make maintenance plannable: Instead of unplanned downtimes, there are targeted interventions based on real condition data.

- Effortless commissioning: Simply mount, connect the plug, done. No calibration, no complex setup required.

- Best integration: Compatible with IBU Plus, IBU Plus NX, Spectra systems, WiFi Box Plus, and other Montronix components.

- Minimal downtime: The response time from the sensor signal to the message from the evaluation unit to the machine control is less than 1 millisecond. This not only protects tools but also keeps your machines productive.

Contact

Would you like to equip your machines with a 3-axis acceleration sensor? Are you looking for a solution for your pumps, spindles, or rotating or linear axes? Then talk to us. We will advise you personally, provide a suitable test solution, and support you until successful integration.

Contact us now

DE

DE  EN

EN  IT

IT