Vibration Analysis and Measurement for Machines and Processes

Unexpected machine damage often occurs due to vibrations that go unnoticed for a long time. Bearing damage, imbalances, or tool breakage announce themselves early before they cause production downtime. With the PulseNG-Diag software, Montronix offers vibration analysis that makes these signals visible and prevents failures.

Learn more now

What is Vibration Analysis?

Vibration analysis is a method that measures vibrations of machines and evaluates the signals. Any deviation from the usual pattern indicates a specific fault, e.g. an imbalance in the spindle, incipient bearing damage, or a loose screw connection. Dull or broken tools also generate conspicuous frequencies that are clearly visible in the signal curve.

Why You Need to Monitor Vibrations

Even small vibrations affect the service life of machine components. They cause higher loads, accelerate wear, and lead to quality problems in workpieces.

Continuous analysis prevents:

- Unplanned downtime: early warning stops machining in time

- Scrap: deviations are detected immediately

- High repair costs: protection of spindle and bearings

Typical Causes of Machine Vibrations

Vibrations do not occur by chance, but always have a specific cause. They are caused by mechanical faults, wear, or incorrect assembly and have a direct impact on process and part quality.

- Imbalances: uneven mass distribution in rotating parts

- Bearing damage: defective rollers or cages generate characteristic frequencies

- Alignment errors: incorrectly mounted components lead to vibrations

- Tool errors: dull cutting edges or breakages generate irregular signals

- Collisions: sudden impacts directly affect the spindle and machine structure

Methods of Vibration Analysis

Our Solutions

For vibration analysis we combine proven sensor technology with intelligent evaluation. The selection of components depends on machine type, tool diameter, and process requirements.

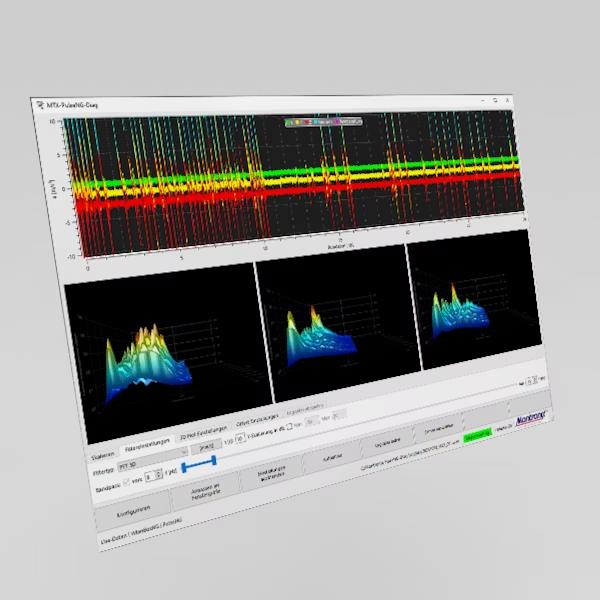

Vibration Analysis with MTX-PulseNG-Diag

The MTX-PulseNG-Diag software records vibrations in real time with sampling rates in the millisecond range. It processes raw data from sensors such as the Pulse Plus with 3-axis measurement and displays them in curves and spectra. Users immediately see whether a machine is running smoothly, whether a bearing shows abnormalities, or whether deviations in the process are indicated.

This gives you a direct basis for interventions in the ongoing process and secures production without delay.

Functions at a glance:

- Storage and comparison of vibration data

- Integration into new and existing systems

- Frequency analysis

- Display of the main vibration axis (Main-ISO)

Advantages of Vibration Analysis for Operation

Higher Machine Availability

Early warnings stop the process before a spindle is blocked by bearing damage or tool breakage causes consequential damage. The analysis detects external vibrations and enables preventive maintenance.

Lower Costs

Vibration analysis makes critical loads visible before expensive damage occurs. A single bearing damage quickly causes repair costs in the five-digit range, which can be avoided. You use tools up to their actual wear limit and thus reduce costs by up to 30%.

Plannable Maintenance

Automatic trend analysis, e.g. by the IBU Plus, documents vibrations over longer periods. The MTX-PulseNG-Diag software shows which components are worn. This allows maintenance to be scheduled for planned downtimes and spare parts to be procured in good time.

Quality Improvement

The analysis detects the smallest frequency changes that indicate dull cutting edges or material deviations. This ensures that companies meet the required tolerances and deliver stable quality.

Areas of Application for Vibration Analysis

- Machining: Machining centers, milling machines, lathes, and grinding machines benefit from the analysis for preventive maintenance.

- Pumps and units: Bearing damage or stiffness can be analyzed immediately.

- Special machines: Whether manual, hydraulic, or electrically driven – every vibration can be analyzed to detect wear or unexpected deviations.

Contact

Would you like to use vibration analysis in your production? We advise you, provide test systems, and support you with integration and training.

Send inquiry nowFAQ: Frequently Asked Questions about Vibration Analysis

What are the advantages of vibration analysis compared to regular visual inspection?

A visual inspection only shows major damage that has already occurred. Vibration analysis detects the smallest changes long before a component fails. This allows maintenance staff to intervene in good time without production interruptions. The method provides an objective database that visual inspections alone cannot deliver.

Which sensor and where to place it in my machine?

For optimal evaluation, a 3D vibration sensor such as the Pulse Plus is best, as it monitors all three orthogonal axes simultaneously. The selection depends on the machine and process. For highly dynamic processes, vibration sensors such as the BV100 are suitable; for precise motion analyses, Pulse Plus sensors are recommended. The important thing is positioning on the right component, such as spindle, tool holder, or machine bed. Montronix supports you in selecting and testing directly on site. The sensor is usually simply attached to the part to be analyzed with its magnetic feet. For measurements with the mobile WiFi Box Plus, the box is also attached in the working area with its magnetic feet, while the maintenance technician stands in front of the machine with a notebook or pad and views the analysis of the MTX-PulseNG-Diag.

Which problems can be most frequently detected with vibration analysis?

Most frequently, the analysis shows bearing damage, imbalances, unusual vibrations, and tool breakages. Resonances or loose components can also be reliably identified. Each of these faults causes typical patterns that are reflected in frequency or amplitude. With the evaluation, errors can be clearly assigned and quickly rectified.

How do I integrate vibration analysis into existing machine parks?

Montronix systems are fundamentally control-independent. For mobile solutions, you connect the sensors to the evaluation units without making changes to the machine control. This means that even older systems can be retrofitted and monitored immediately. For permanently installed systems, an adaptation of the machine control is necessary, as the evaluation is permanently integrated. Companies benefit from seamless integration into the production process and continuously receive data that can be used directly for process optimization.

DE

DE  EN

EN  IT

IT