The "non-contact" AT100 AccuTorque and force sensor combined with the TSTA2 amplifier and connected to a SPECTRA™ electronic unit is the perfect solution for:

- Tool state recognition

- Broken tool detection

- Determination of process states

- Optimize processes

- Quality assurance

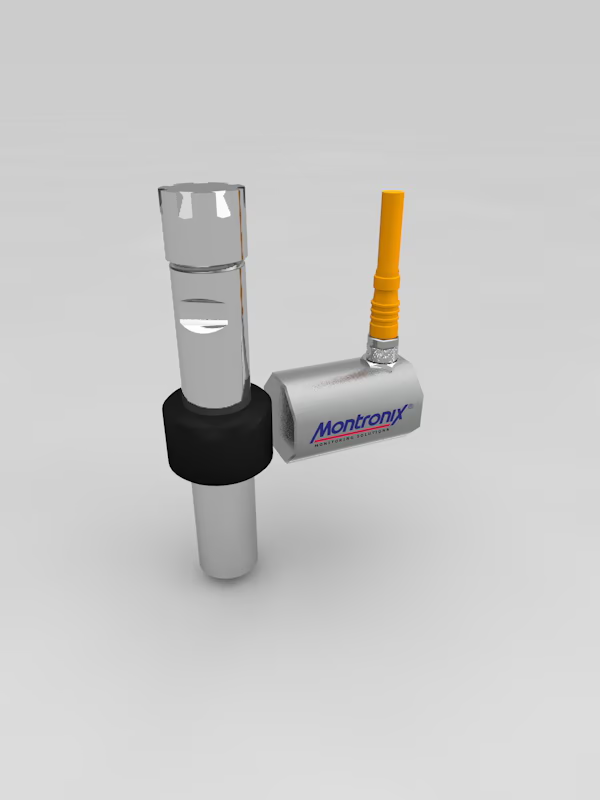

The AccuTorque torque sensor provides a direct measurement of torque and thrust. AccuTorque can be used to detect tool failures and to verify process quality. Available in 3 versions, the AccuTorque sensor is incorporated into a rotating shaft, such as a spindle or tool holder, where it transmits the signal across a 5 mm air gap to a non-rotating stator. The stator receives the data and transfers it to the amplifier for signal conditioning before being sent to the control unit for processing.

Torque measurements are primarily used in rotating tooling applications where power monitoring is inadequate. Applications may include drilling, tapping or machines with multi-spindle heads. AccuTorque is used to detect tool failures and verify process quality such as thread depth and hole.

Thrust is used to detect a missing tool and determine that a process is performing as expected.

The AccuTorque sensor is supplied with a signal conditioning amplifier. This amplifier is sealed (IP67 rating), and can be placed within the machining environment.

The amplifier is attached to the non-rotating stator using a 5 meter cable. Cables up to 30 meters long can connect the amplifier to the controller.

DE

DE  EN

EN  IT

IT